In such cases, the ejector provides rapid initial mixing, a fine bubble dispersion and, if properly designed, good liquid mixing in the vessel.

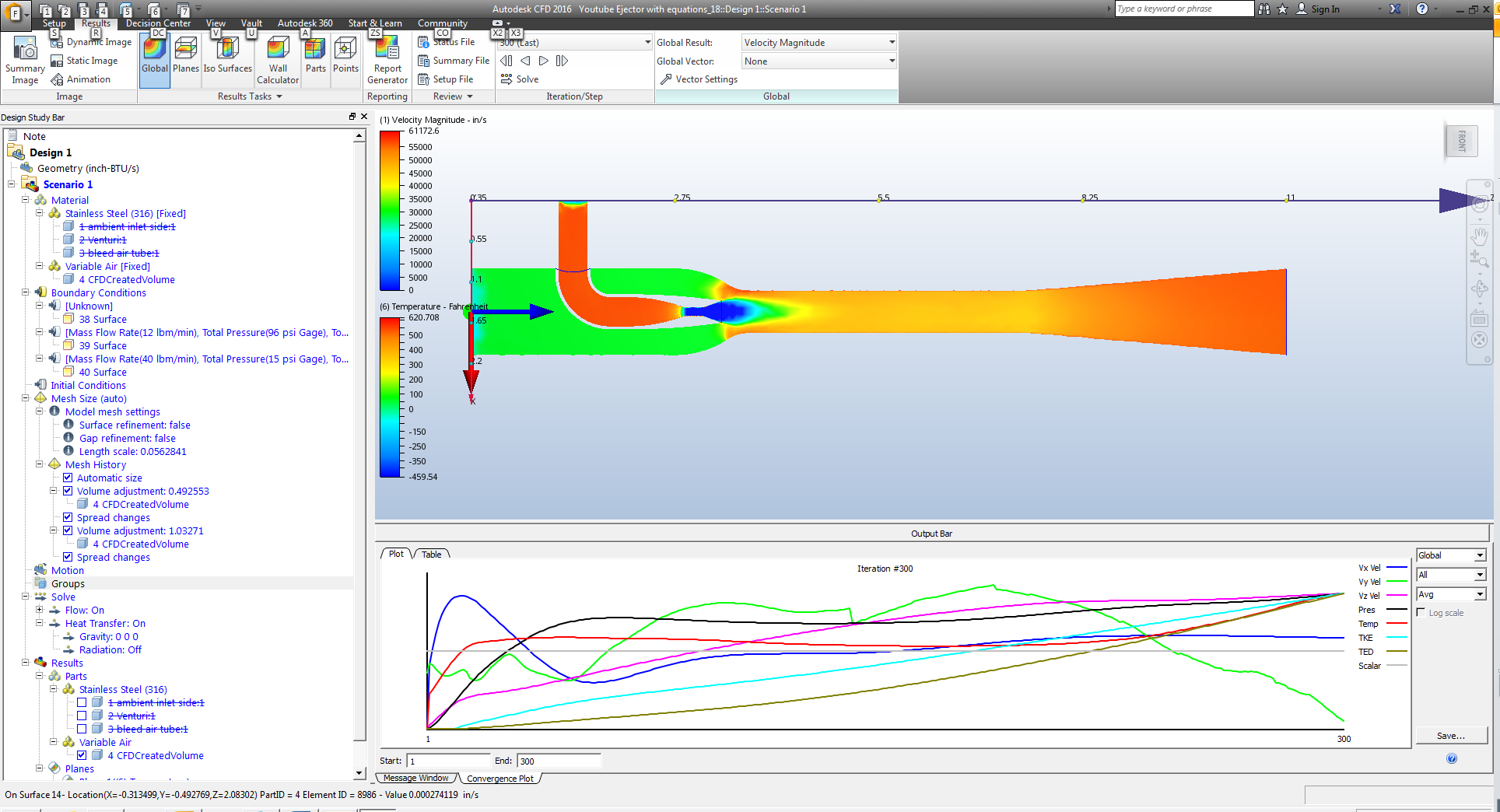

Where longer residence time is required, ejectors are often combined with a contact vessel. This leads to mass transfer coefficients typically 2-3 orders of magnitude greater than a typical stirred tank, making them particularly suited to absorption with rapid, competing chemical reactions where fast mixing is required to reduce byproduct formation. They have the combined benefits of being able to draw in gas without the need for compression, and providing a very fine dispersion in the mixing tube.Įjectors are characterized by cocurrent plug flow in the mixing tube, with very high energy dissipation rates (typically in the range 100-1,000 W/kg), but short residence times (less than 1 second). They can be used either as stand-alone devices, or in combination with a contact vessel. Gas-liquid ejectors can be very effective devices for mass transfer applications. A further decrease in mixing tube diameter (or any attempt to increase secondary flow) causes performance to decrease rapidly.ĭesign requirements for the nozzle, mixing tube and diffuser are similar to those for jet pumps. Performance increases by reducing mixing tube diameter up to a point where the expanding supersonic primary jet almost fills the mixing tube before mixing can take place and choking occurs.

A complex graphical method is available in ESDU 84029.Īs with a jet pump, the key geometric factor in the design is the mixing tube diameter. Owing to the complexity of the equations, these cannot be solved directly. Performance can be then calculated by considering conservation of mass, momentum and energy in the mixing tube and diffuser. However, work by Ashton, Green and Reade (1993) suggests that the use of a diverging section is not necessary for effective operation, at least at moderate pressure ratios. An 'on-design' condition can be defined where the static pressures of primary and secondary flows are equal at the nozzle exit. In some ejector designs, a converging-diverging nozzle is utilized to accomodate the expanding jet. (See Critical Flow, Jets and Nozzles.)ĭownstream of the nozzle, flow will expand in a series of supersonic shocks until the pressures of both streams become equal and mixing occurs. Where C D is the discharge coefficient, S TH the throat area, γ the ratio of specific heat at constant pressure to the specific heat at constant volume and R, the specific gas constant.

0 kommentar(er)

0 kommentar(er)